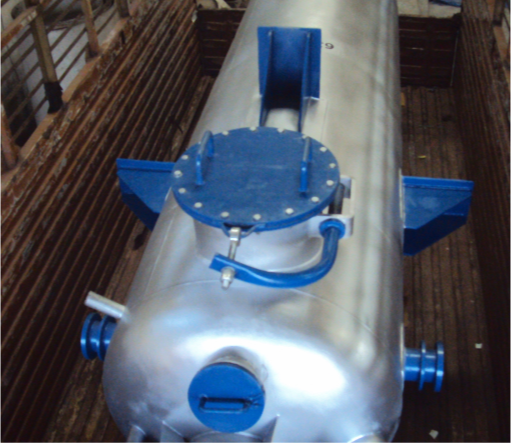

Reactors

Manufacturing Stainless Steel Chemical Reactors

Edesign specializes in manufacturing stainless steel chemical reactors tailored for diverse industrial applications in oil, chemical, rubber, pesticide, dye, medicine and food industries. These reactors are pivotal in processes such as vulcanization, oxidation, alkylation, polymerization and condensation, crucial for enhancing product quality and efficiency across various sectors.

Precision Engineering for Versatile Applications

Oil and Chemical Industries: Our stainless steel reactors are engineered to withstand harsh chemical environments and ensure optimal performance in refining and synthesizing processes. They are designed with corrosion-resistant materials and advanced insulation techniques to maintain product integrity and operational efficiency.

Rubber and Pesticide Production: Reactors in rubber and pesticide production require precise temperature and pressure control to facilitate chemical reactions effectively. Edesign stainless steel reactors are equipped with state-of-the-art temperature regulation systems and robust mixing mechanisms to meet the stringent requirements of these industries.

Dye and Medicine Manufacturing: Precision is paramount in dye and medicine manufacturing. where reactors must maintain strict conditions for synthesis and formulation processes. Our reactors are designed to ensure uniform mixing and precise temperature control, essential for producing high-quality dyes and pharmaceuticals.

Processing of food: Hygiene and safety are of the utmost importance in the food industry. Edesign stainless steel reactors are crafted with sanitary design features to meet food-grade standards while facilitating processes like fermentation and extraction. They are easy to clean and maintain, ensuring compliance with regulatory requirements.

Advanced Technologies for Optimal Performance

Vulcanization: Reactors used for vulcanization in rubber manufacturing require precise heat and pressure management to achieve optimal cross-linking of polymers. Edesign integrates advanced heating systems and efficient agitation methods to enhance the vulcanization process, ensuring superior product quality and consistency.

Oxidation and Alkylation: Chemical processes such as oxidation and alkylation demand reactors capable of handling diverse chemical reactions under controlled conditions. Our stainless steel reactors are customizable to accommodate varying process parameters, ensuring flexibility and scalability in production.

Polymerization and Condensation: Reactors for polymerization and condensation reactions require robust construction and precise control over temperature and pressure profiles. Edesign expertise in stainless steel reactor design ensures reliable performance and efficient scale-up of production processes.

Solid-Liquid Suspension

Suspension refers to a mixture of liquids and solids that are distributed in a heterogeneous manner within it. Edesign suspending is the process of combining these two substances. There are a variety of objectives that can be achieved with a suspension agitator. For example for the dissolution of solids, fluidization of the solid near the bottom may be sufficient. In continuous processes like crystallization or ore leaching, high demands are placed on the homogeneity of the suspension.

Factors to consider include the process requirement (whether to suspend completely or homogeneously) the difference in density between fluid and solid and the particle size of the solid.

Why Choose Edesign?

We combine extensive industry experience with innovative engineering to deliver stainless steel chemical reactors that exceed expectations. Our commitment to quality, reliability and customer satisfaction drives us to continuously innovate and optimize reactor solutions for our clients.

Whether you are in oil refining, chemical synthesis, rubber manufacturing or food processing. Edesign offers customized stainless steel reactor solutions designed to enhance productivity and minimize operational costs. Contact us today to discover how our advanced reactor technologies can elevate your manufacturing processes.